Plunge Platten – Universal kit

€244.04 Inc. GST

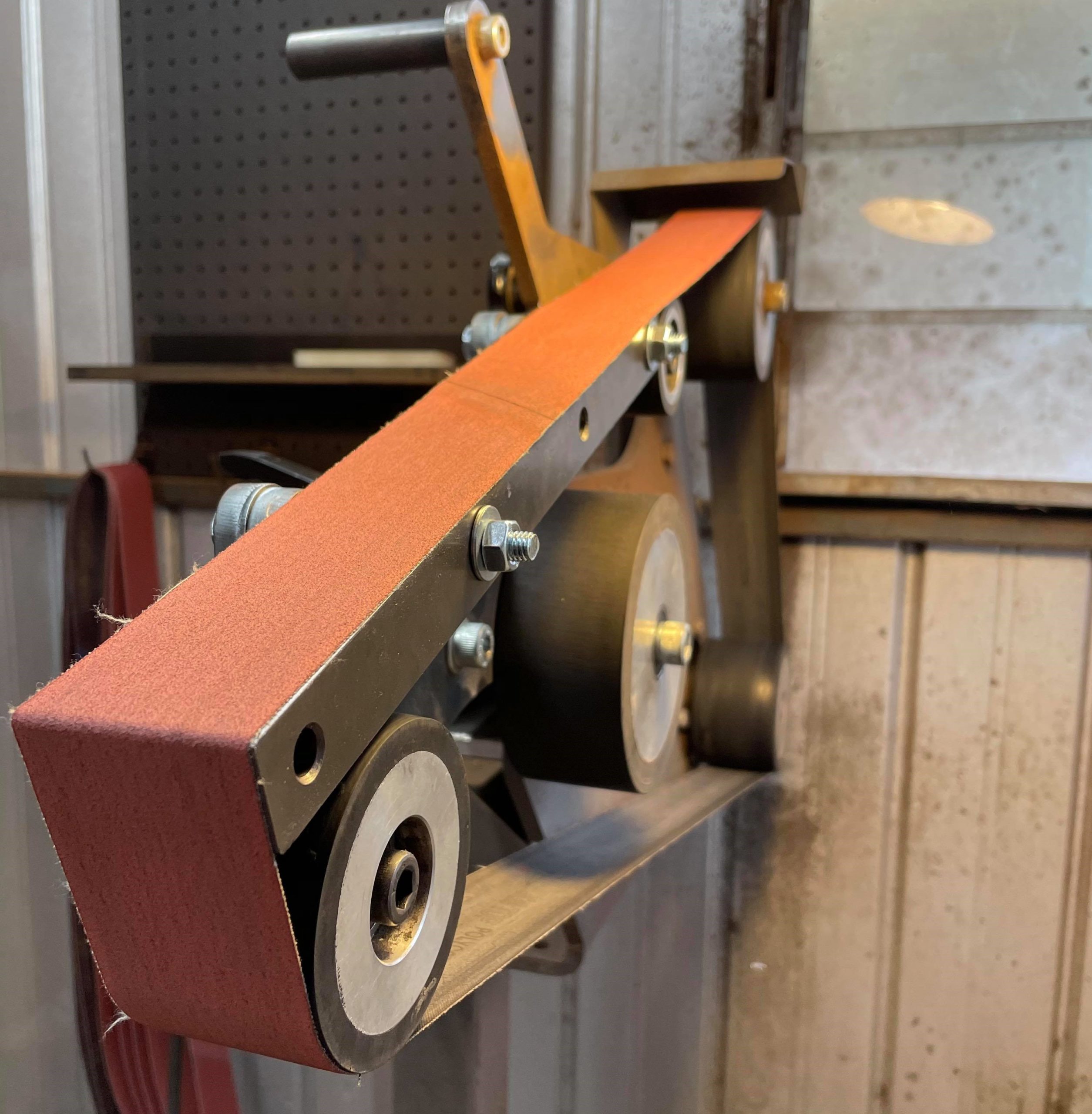

The Plunge Platen enables knife makers to quickly grind perfect plunge lines perpendicular to the blade. Utilising all 4 corners of the hardened platen and a wheel mounted underneath to help transition the belt. This drastically reduces the time spent finishing blades and will give you perfect symmetry to your plunges.

7 in stock

Description

NEW MK.2 Plunge Platen

***NOW AVAILABLE***

The Plunge Platen enables knife makers to quickly grind perfect plunge lines perpendicular to the blade. Utilising all 4 corners of the hardened platen and a wheel mounted underneath to help transition the belt. This drastically reduces the time spent finishing blades and will give you perfect symmetry to your plunges.

Utilising all 4 corners of the platen with different sized radii consisting of 1.0mm, 2.0mm,3.0mm, and 4.0mm.

These are designed to be a universal fit on most 2×72 4-wheel design belt grinders.

And also include a direct spigot mount for 84 engineering grinder tool arms.

So far they are confirmed to fit on:

84 Engineering Shopmaster 72″, Gibson, noob and Shopmate 48″.

Firepants Fab Fireant

ARJ 2×72″

Geeky Stuff:

K110 hardened to 58-60 Rockwell C. has been tempered at 500c to induce a secondary hardening process in this type of steel. This enables the platen to withstand higher than normal operating temperatures without losing hardness and wear resistance.

This also means that the platens have a higher wear and heat resistance than mild steel and is the perfect foundation for nitriding.

Gas nitrided by introducing ammonia into the nitriding chamber at 500c, this causes the ammonia to crack from the heat releasing nitrogen onto the part. this process hardens the surface even further (10 thousandths deep).

This creates an extremely wear-resistant part, that is supported by the hardened k110. whereas if the part was just unhardened mild steel, you will find that the part is extremely hard on the surface but will collapse in on itself as its core is too soft.

The last process that we do to these platens is called shot peening, which promotes a high lubricity to the surface of the part. This reduces friction and heat build-up

All 3 of these processes coupled together create an astonishingly robust platen that is capable of taking extreme forces of friction.

-

Technical specifications

Material: K110 (D2 tool steel)

Hardness: 58-60 rockwell base hardness, 64-66 rockwell nitrided surface.

Size: 200mm L, 55mm W, 30mm H

Included in the kit: 2 x nuts and bolts, 4 washers, 2 mounting arms and 2 spacers, mounting spigot, grinder wheel and bracket.

Based on Kyle Royer’s idea, This is Minno Creek Knife and Tool’s version of his Plunge Platen.

This product is covered by our limited warranty.

keep in mind this product is a consumable and will eventually wear over time from normal use.

Additional information

| Weight | 5 kg |

|---|---|

| Dimensions | 300 × 60 × 30 mm |

| Manufacturer | Minno Creek Knife and Tool |

| Warranty | 12 Months limited warranty. |

| Material | K110 (D2 tool steel) |

| Hardness | 58-60 rockwell base hardness, 64-66 rockwell nitrided surface. |

| Product Size | 300mm L, 55mm W, 25mm H |

| Universal Kit includes | 2 x nuts and bolts, 4 washers, 2 mounting arms and 2 spacers |

Reviews

There are no reviews yet.